FRP Composite Material

Fiber Reinforced Polymer (FRP) composites are revolutionizing our society and impacting our daily lives by giving us products to use that are lighter, more durable and have infinite design flexibility. But what exactly is FRP material?

Composites are created by combining two or more materials to produce a new FRP material that retains important properties from the original components. These unique combinations deliver significant advantages over traditional materials in structural applications.

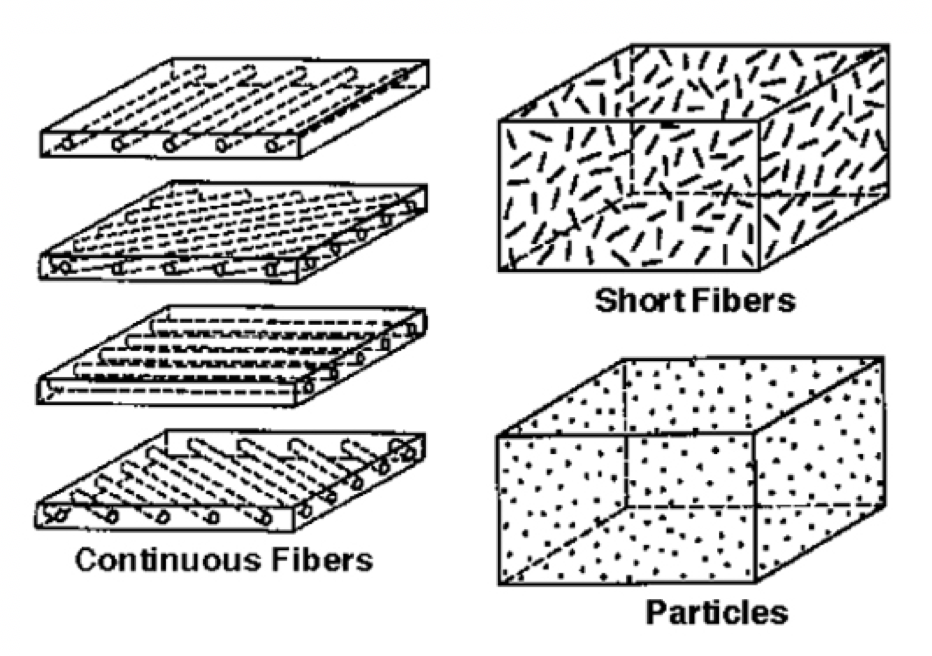

FRP Composites consist of a polymer matrix material that is reinforced with fibers. The reinforcing fibers provide the primary structural performance of the material, with the polymer transferring the load from fiber-to-fiber and protecting the fibers from the operating environment (water, heat, cold, chemicals, UV and insects.) Reinforcement may be continuous fibers, discontinuous fibers or particles.

For manufacturers, composites offer a flexible solution with the advantage of being able to select just the right combination of fiber reinforcement and polymer material to meet the application requirements.

At DICA, our FiberMax Crane Pads and FiberMax composite stabilizer pads are manufactured using FRP Composites. These products utilize continuous fiber reinforcements (see graphic above) for maximum structural properties and polymers such as polyester, vinyl ester and epoxy.

The Advantages of Composites

- Lightweight

- The design can be optimized to meet stiffness, strength and manufacturing requirements

- Resistant to corrosion

- Resistant to fatigue damage with good damping characteristics

Where It Counts

Weight: Composites, due to lower density, can deliver a weight savings of 25 to 50 percent over traditional materials. Composite densities range from 0.045 lb/in3 to 0.072 lb/in3 as compared to 0.10 lb/in3 for aluminum and 0.29 lb/in3 for steel. While some applications may require thicker composite sections to meet strength/stiffness requirements, uses will still enjoy a significant weight reduction.

Cost: FRP composites provide value as innovative solutions to customer problems. With all the benefits of FRP composite, acquisition costs may be higher than traditional materials, but the savings from low maintenance and long life make FRP composites a lower cost choice over time.

Composite performance: Composites provide improved performance benefits over metals due to their inherent properties. The strength-to-weight and stiffness-to-weight ratios are the major reasons composites are used. The polymers provide excellent resistance to chemicals and corrosion and enable FRP composites to thrive in environments that degrade wood, steel or concrete. The wide range of fibers and polymers available, make it possible for manufacturers to choose the optimal FRP material combinations to meet the specific structural requirements of an application.