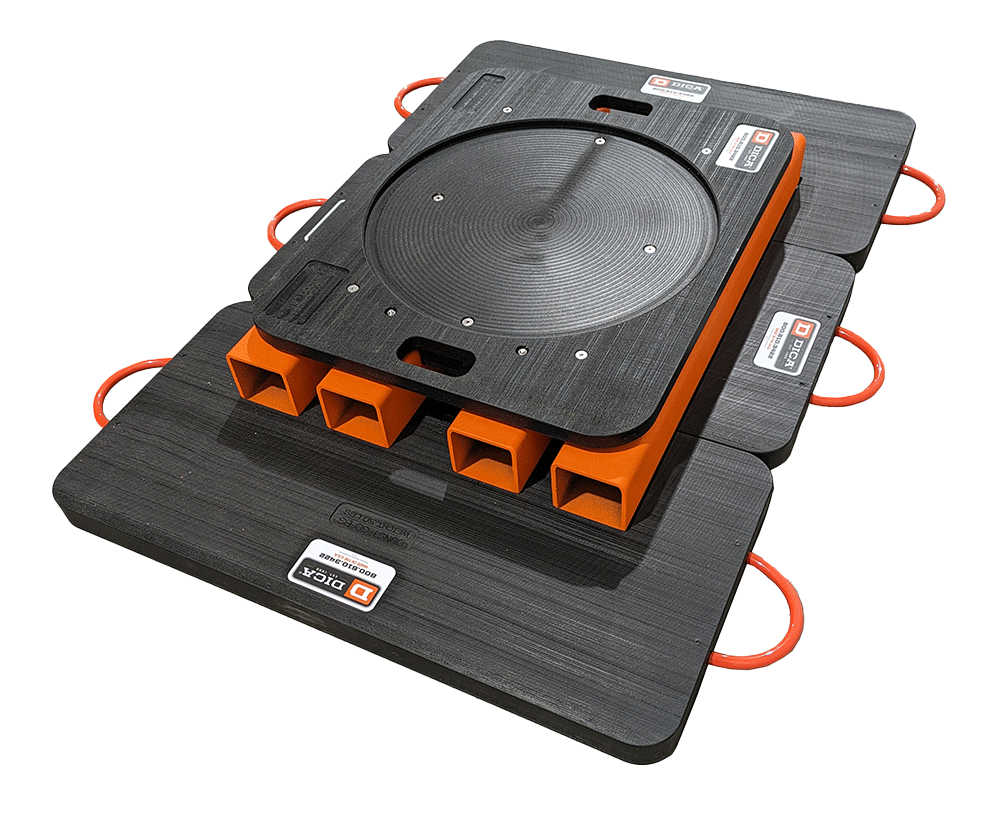

STEEL TECH – DUNNAGE PAD SYSTEM

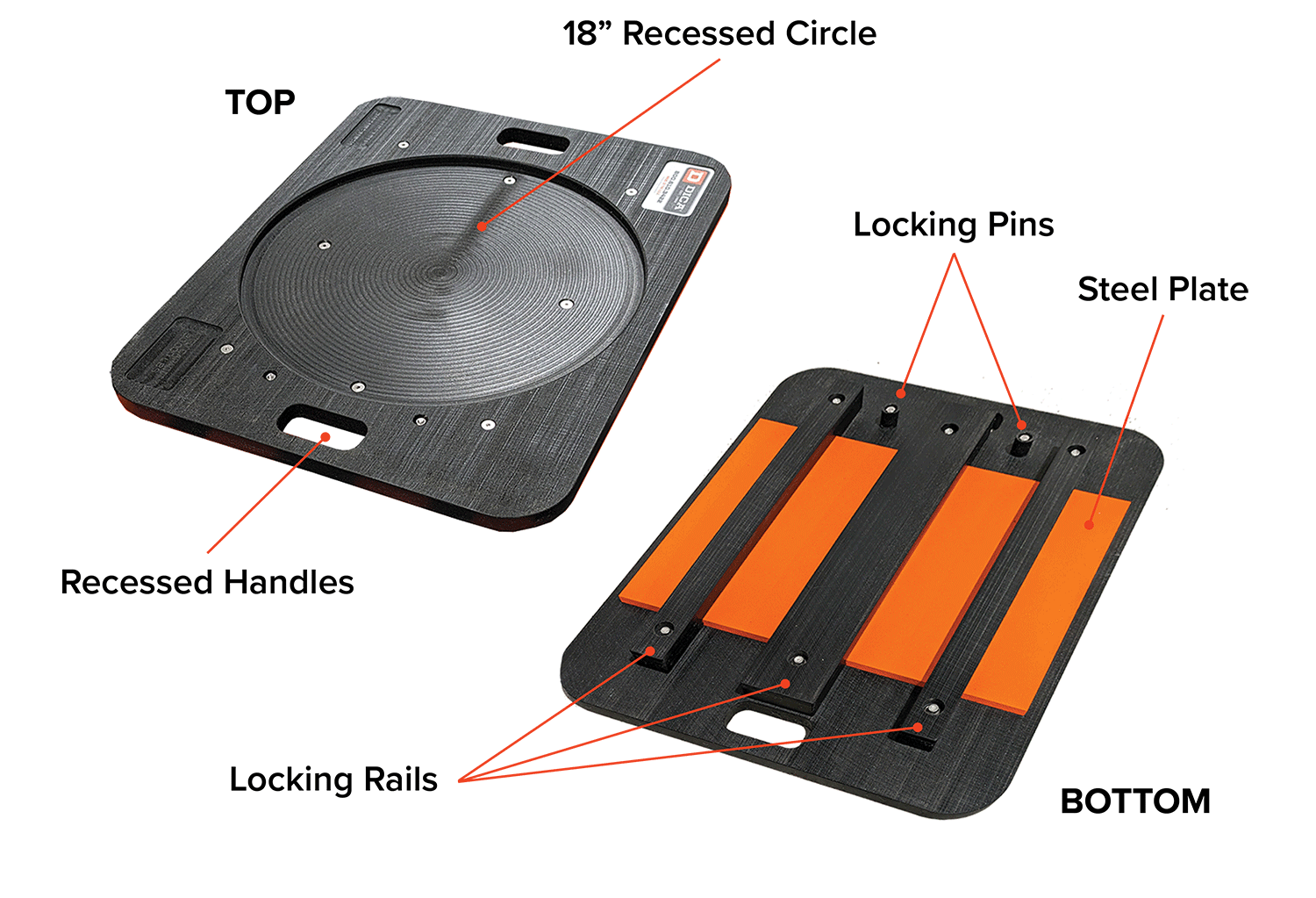

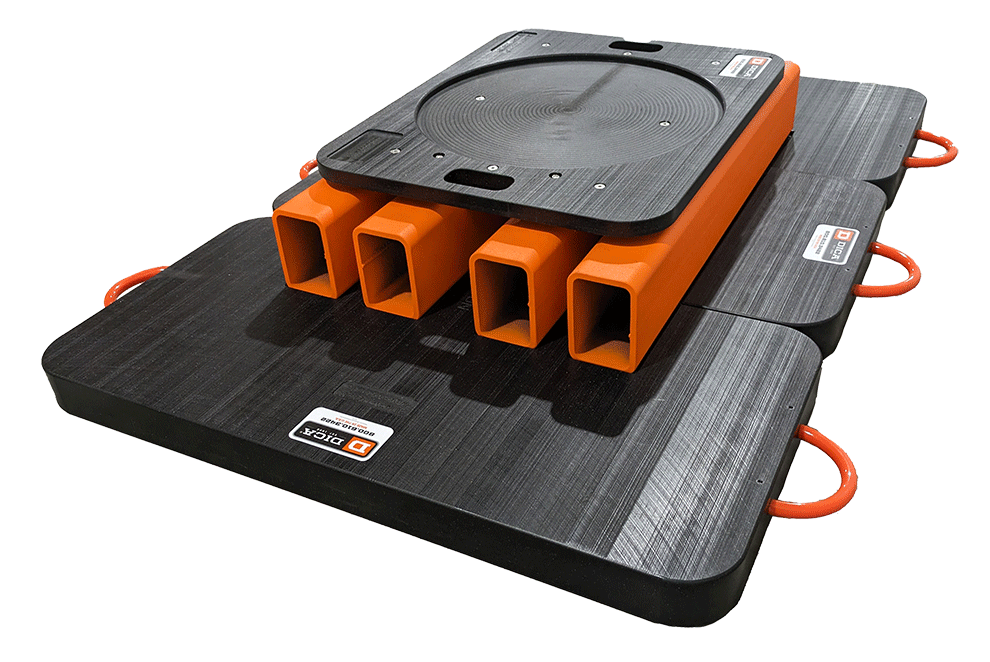

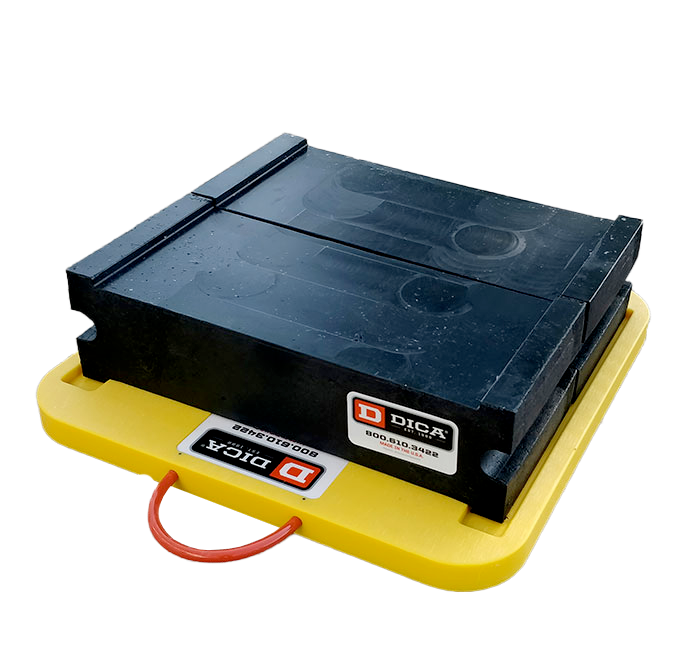

DICA’s multi-pad system utilizes the unique properties of steel and DICA’s engineered thermoplastic. The patent-pending modular steel dunnage system is specifically designed for the daily challenges concrete pump operators face and can be deployed by a single person to reduce ground bearing pressure.

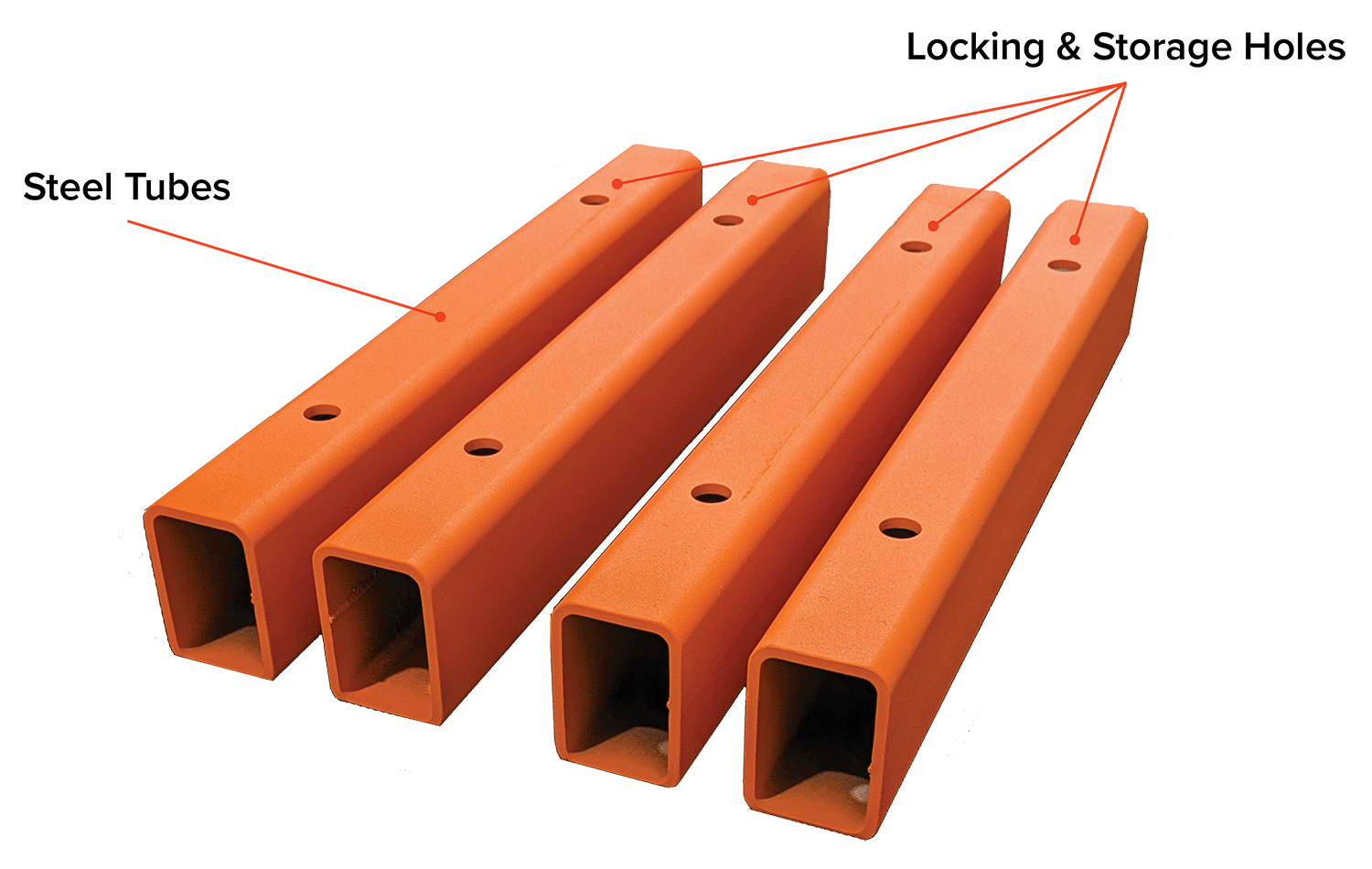

SteelTech – Dunnage Pad System uses the lightest weight steel and the lowest cost parts that when combined, creates a unified solution that is repeatable, long lasting and efficient.

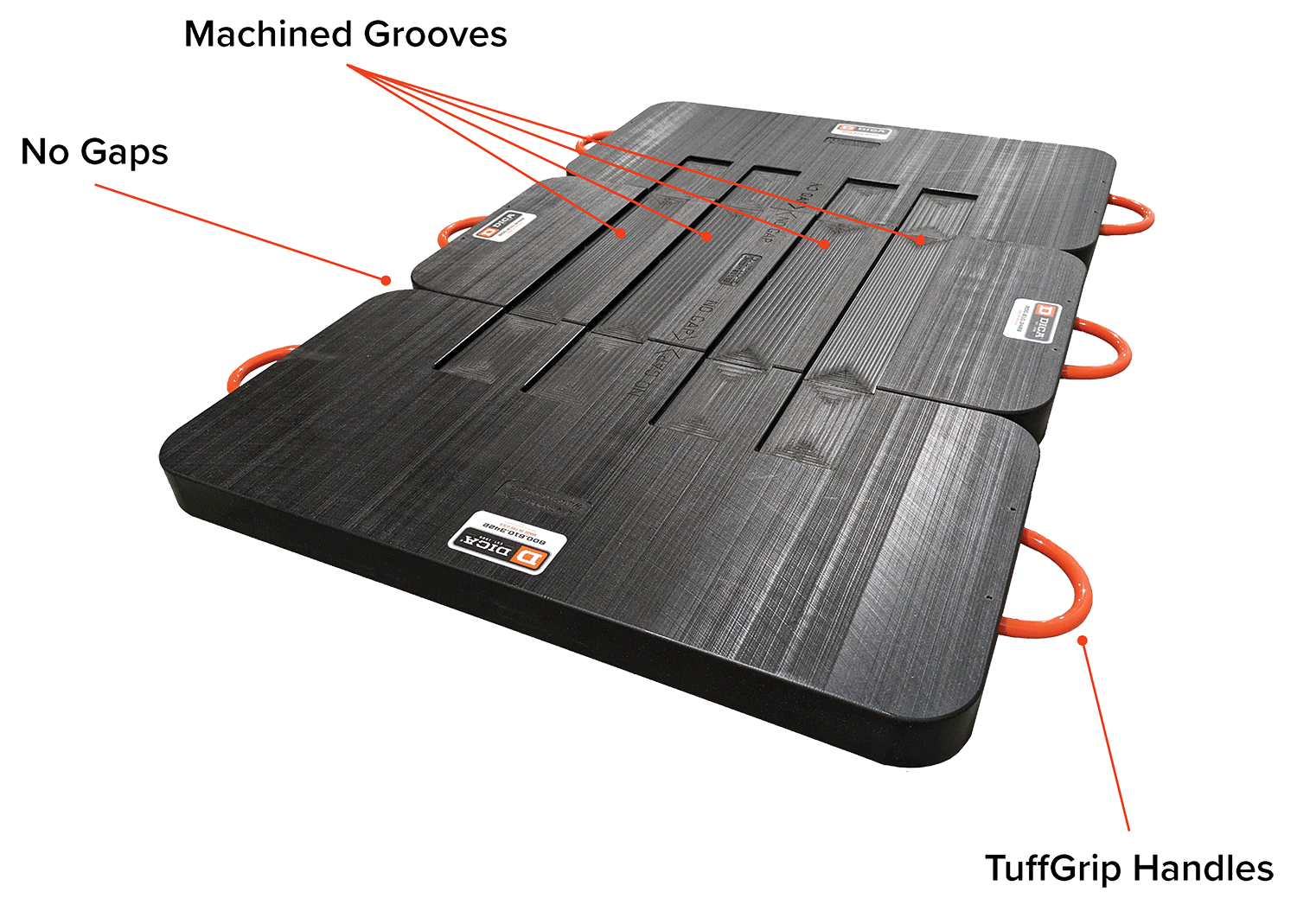

- Lightweight solution is packed into a one-person modular system that incorporates the best of steel and plastic.

- Fully engaged system that reduces ground bearing pressures efficiently and effectively.

- Designed for small outrigger floats commonly found on concrete pump trucks.

- Materials will never rot, warp, splinter, delaminate, deteriorate or waterlog.

- Engineered and manufactured in the USA.