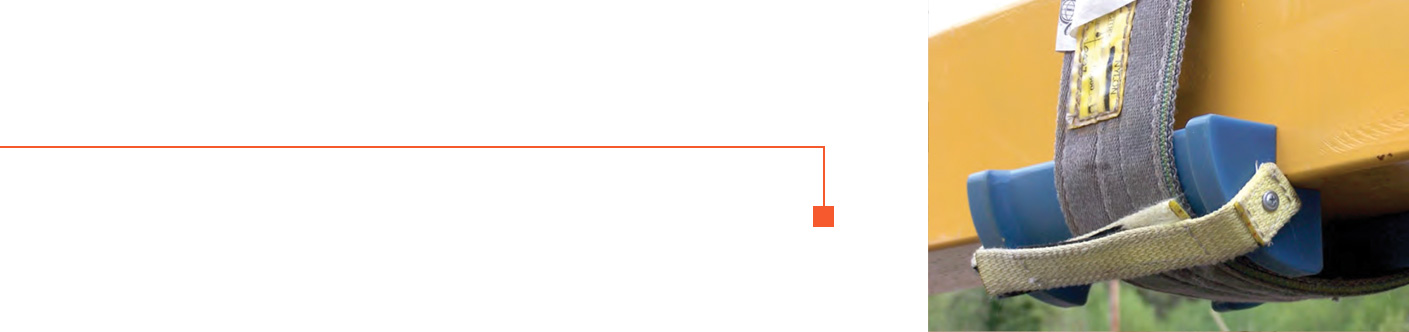

PROTECT SLINGS & LOADS

LiftGuard Sling Protectors prevent damage to slings caused by contact with edges, corners, or protrusions from loads being lifted. They also keep the sling away from other significant contact points during lifting operations.

MEDIUM DUTY

Ideal for use with synthetic slings. They can be used with wire rope and chain slings.

HEAVY DUTY

Enhanced durability allows for use with all synthetic, wire rope and chain slings.

BEAM & PLATE

Specifically designed to be used with lifting steel I-beams and steel plate.

COIL UNITS

Specifically designed to be used when lifting coils of steel, or similar objects.

![]()

WE’LL PUT OUR MONEY WHERE OUR MOUTH IS.

WHY DEMAND DICA?

We specialize in building engineered products that maximize performance and solve important problems for your team.

Our products are developed and manufactured with patented designs and process to create safer working conditions for you.

DICA family values are focused on building long lasting win-win relationships that can solve new challenges together.

LET US HELP YOU

Sling Protector sizing help is just one click or call away.

ABOUT US

CONTACT US

Email

Contact Us

sales@dicausa.com

Call

Toll Free: 800-610-3422

Company Headquarters

4101 120th St.

Urbandale, IA 50323