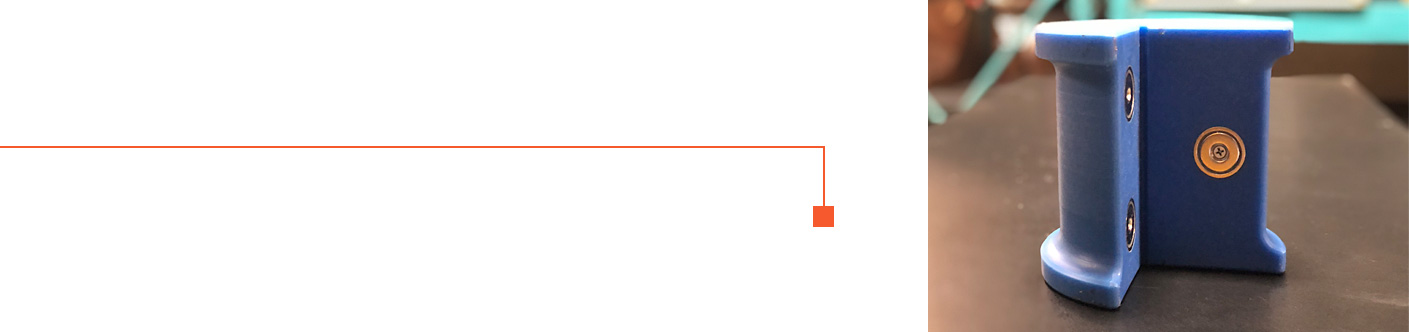

LIFTGUARD COIL SLING PROTECTORS

Coil units allow for a secure protector fit within the center and on top of a steel coil. Custom size coil lifting sling protectors are available for different coil bore diameters, or to accommodate larger sling widths.

LiftGuard Center Coil Sling Protectors are designed to be used INSIDE the bore or the center of a steel coil. The horizontal surface of the center coil unit is convex and fits the inside of a coil.

LiftGuard Top Coil Sling Protectors are designed for THE TOP of the steel coil. Both the horizontal and vertical surfaces are flat, neither surface is curved.

LiftGuard Coil Sling Protectors help ensure OSHA & ASME compliance:

- OSHA 1926.251(c)(9) Slings shall be padded or protected from the sharp edges of their loads.

- ASME B30.9 “Slings in contact with edges, corners, or protrusions should be protected with a material of sufficient strength, thickness, and construction to prevent damage to the sling.”

- Eliminates sling damage

- Superior abrasion and wear resistance

- Magnetic – they stay where you put them

- Made from a non-metallic, High-Performance Cast Nylon

- Heat stabilized to allow for safe operations at higher temperatures

- Patented design and Made in the USA