SLOT LOCK INTERLOCKING CRIBBING BLOCKS

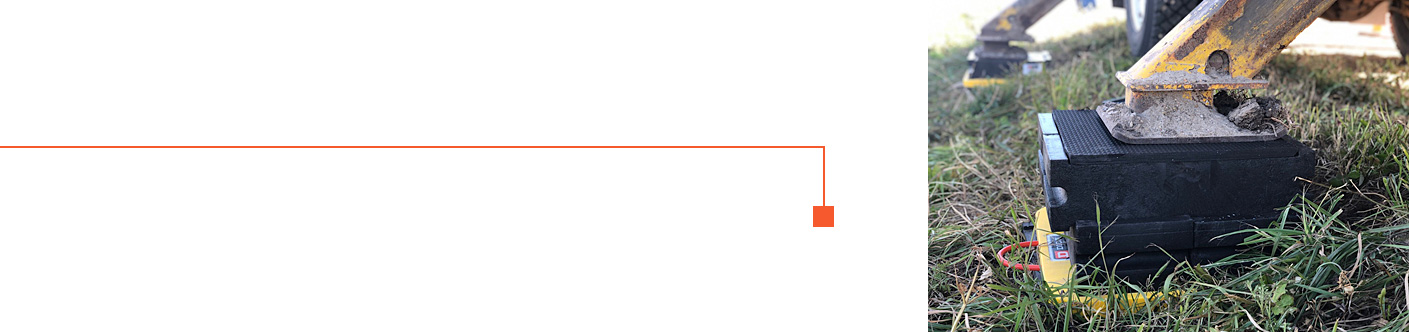

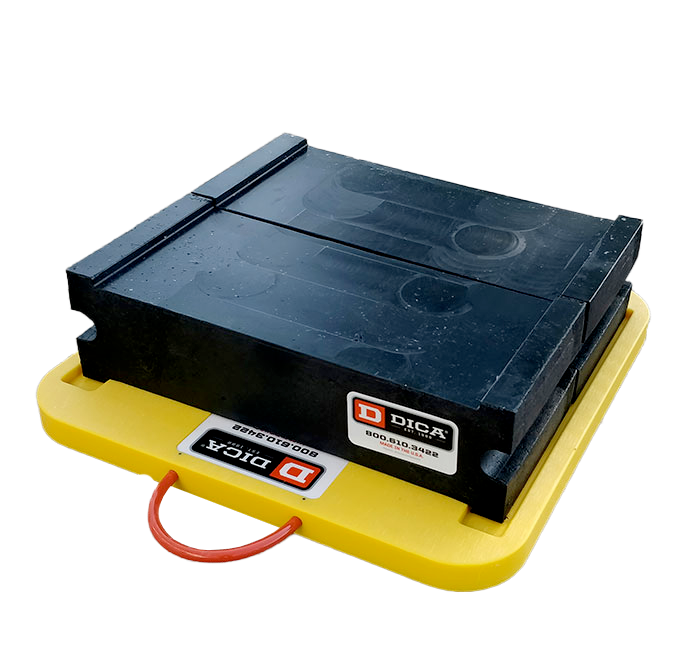

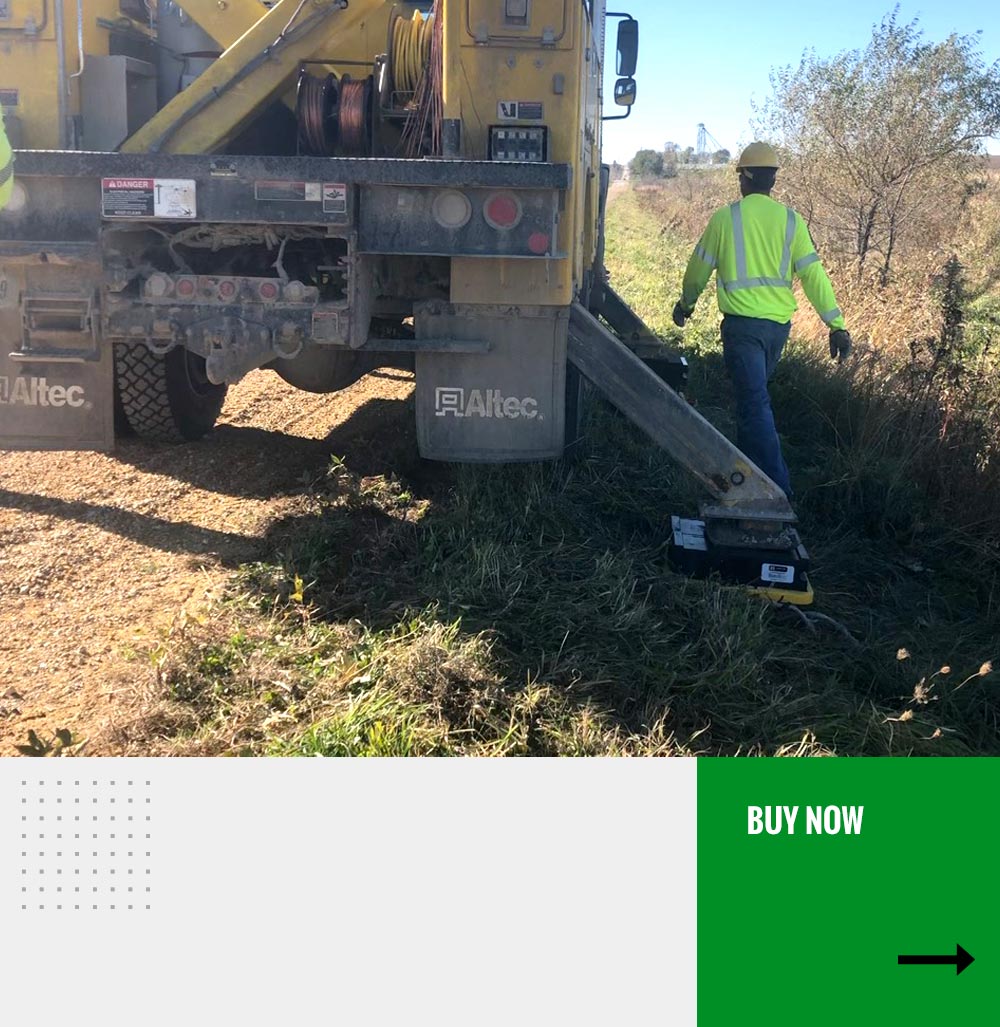

Crib up with DICA’s ProStack® Slot Lock Interlocking Cribbing Blocks. Slot Lock Blocks stack and interlock for optimum stability. DICA Cribbing Blocks are compatible with SafetyTech Outrigger Pads giving operators the safety, stability and versatility they need when working in challenging conditions.

DICA patented (US Patent 11,479,939) slot and flange interlocking system, integrates with SafetyTech Outrigger Pads to increase bearing area and decrease ground bearing pressures. Slot Lock Blocks are designed for operating equipment and static load applications.

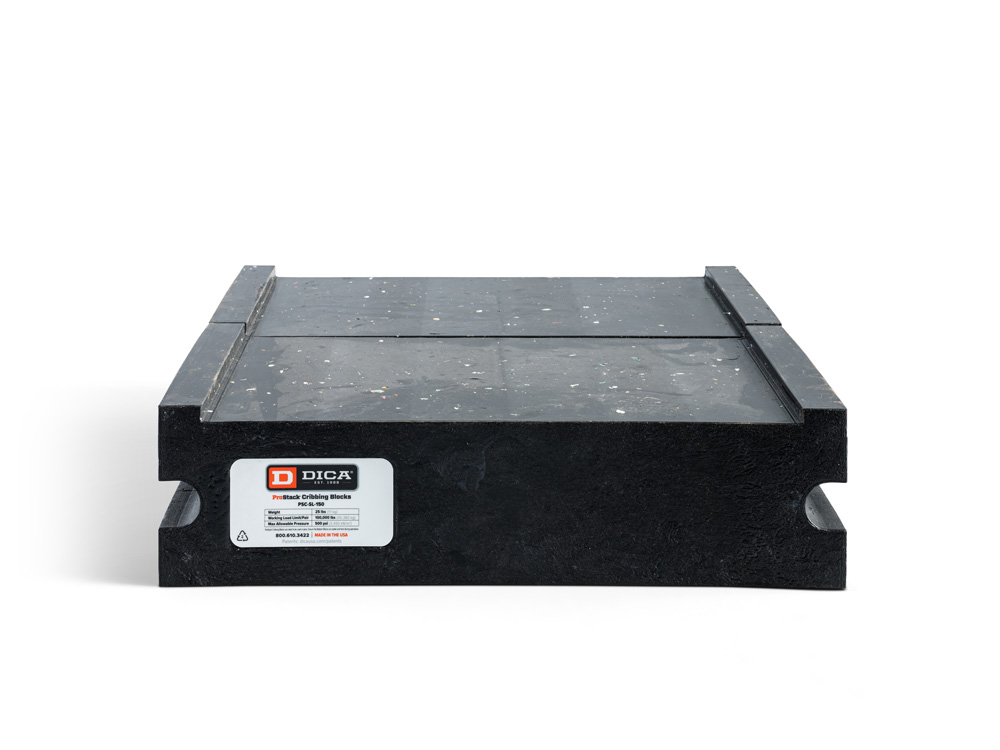

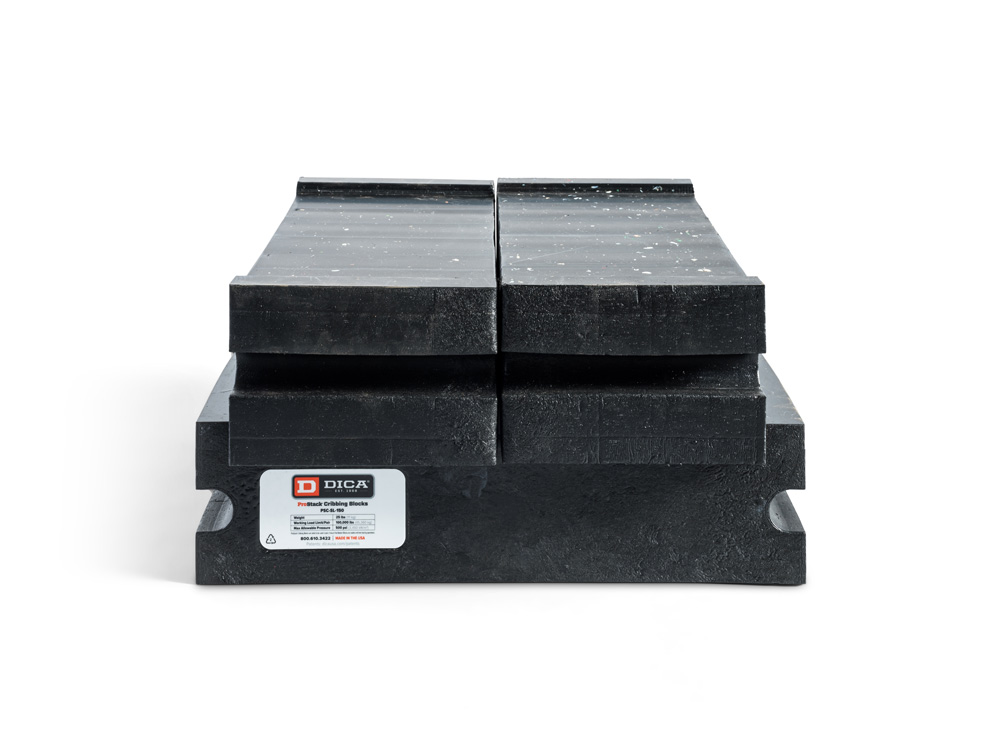

- Stacking height is 5.0″ per block.

- Weight = 29 lbs. per block

- Built-in hand grips allow for easy pickup, carry and placement.

- Contact surface is 18″x18″ when two blocks are placed side by side.

- Will not splinter, crack, rot or delaminate.

- Working load limit is 100,000 lbs when used in tandem.

- Made in the USA with environmentally friendly recycled material.