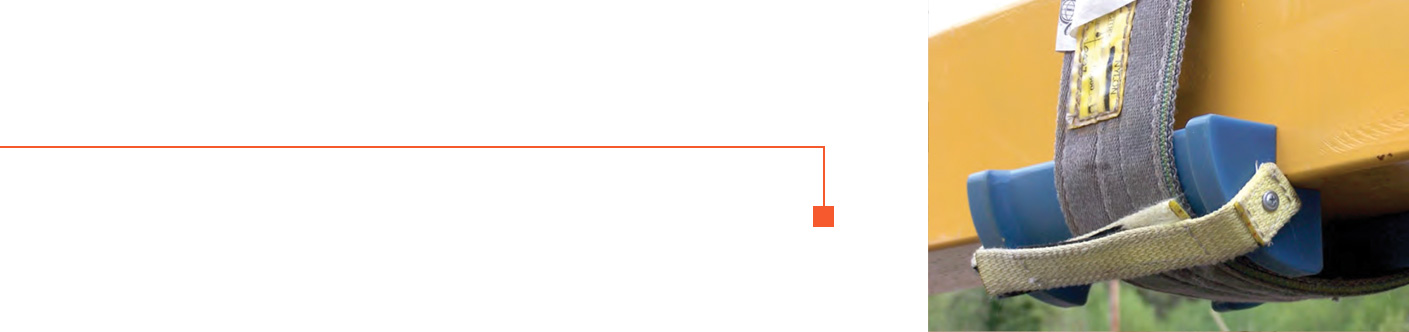

LIFTGUARD GUARD MEDIUM & HEAVY DUTY SLING PROTECTORS

Magnetic LiftGuard Sling Protectors securely fasten to loads and are engineered to protect slings from damage caused by contact with edges, corners, or protrusions.

Medium Duty edge protectors are ideal for use with all synthetic web slings. Heavy Duty Units can be used with synthetic slings but are specifically designed for the high pressure needs of wire rope and chain slings.

LiftGuard Units are magnetic which allows for easy and secure placement for riggers. All magnets are slightly recessed to prevent their damage and ensure a connection without scratching the load surface.

LiftGuard Medium and Heavy Duty Sling Protectors help ensure OSHA & ASME compliance:

- OSHA 1926.251(c)(9) Slings shall be padded or protected from the sharp edges of their loads.

- ASME B30.9 “Slings in contact with edges, corners, or protrusions should be protected with a material of sufficient strength, thickness, and construction to prevent damage to the sling.”

- Eliminates sling damage.

- Superior abrasion and wear resistance.

- Magnetic – they stay where you put them.

- Made from a non-metallic, high performance cast nylon.

- Heat stabilized to allow for safe operations at higher temperatures.

- Patented design and Made in the USA