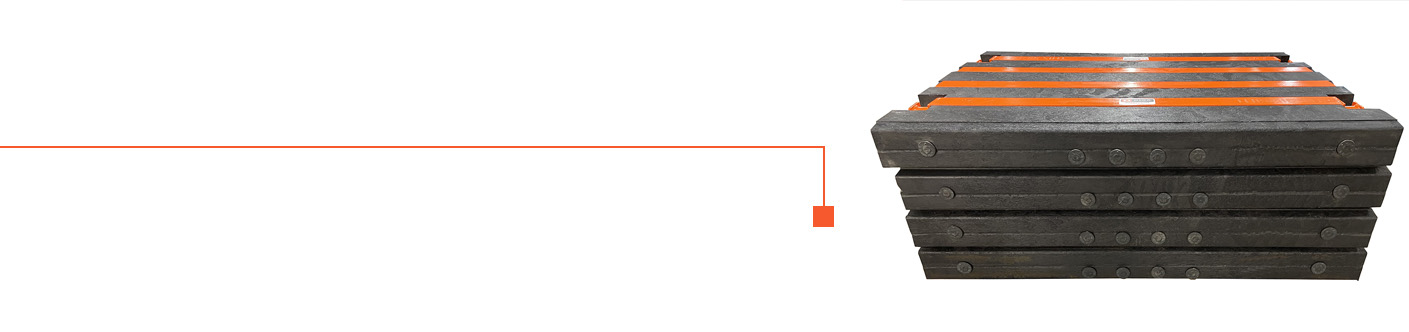

ECOMAX

CRANE PADS

EcoMax® Crane Pads are engineered to spread load, reduce ground bearing pressures and ensure the stability of crane equipment during operations. DICA’s unique patented design combines the stiffness of steel with the durability of composite to create a crane pad that can outlast the crane it’s supporting.

EcoMax Crane Pads are unlike any other crane pad in the world. By combining the stiffness of steel, the durability of composite material and the connectivity of I-beam flanges with unique through-bolt positioning, DICA has engineered a crane pad optimized for cost, durability and performance.

- Engineered solution combines composite and steel to ensure stability of equipment.

- Performance does not change based on age of product, usage or environmental effects.

- Designed for everyday use with easy set-up and tear down.

- Patented design effectively distributes the load evenly throughout the entirety of the crane pad.

- Manufactured in the USA with recycled plastics, fiberglass (Fiber Reinforced Composite), steel I-beams and steel tie rods.