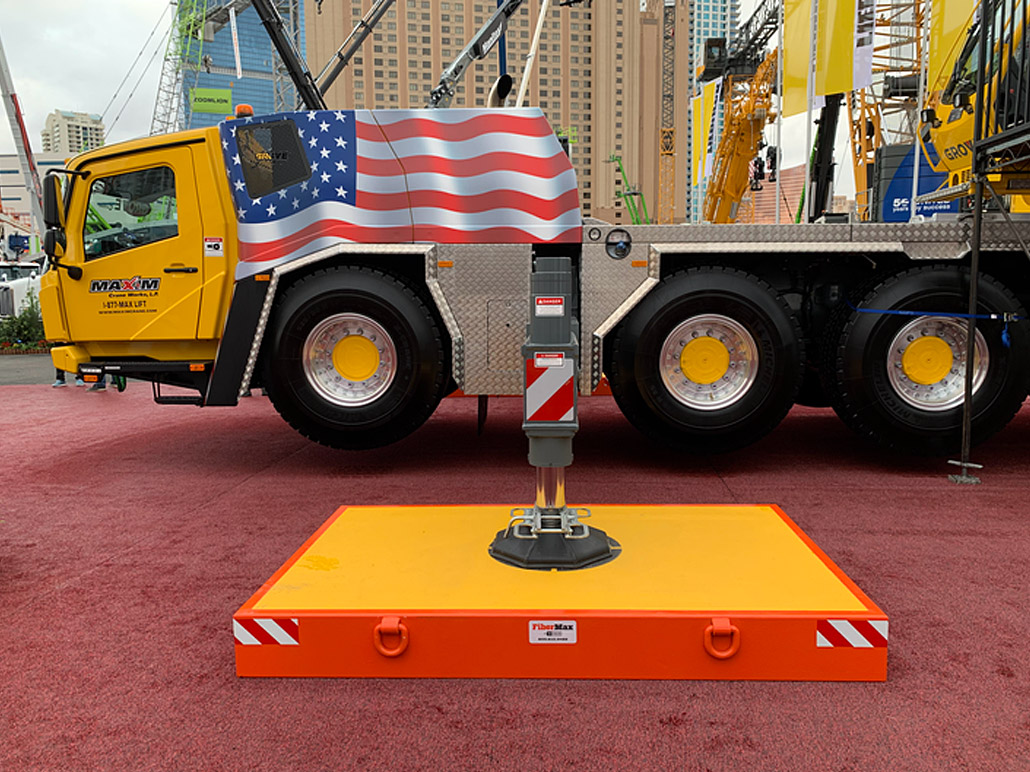

FIBER MAX

CRANE PADS

FiberMax® Crane Mats provide similar strength and stiffness characteristics as steel crane mats but weigh up to 60% less. This significant weight reduction results in lower transportation costs and faster setup and tear down times.

Made from Fiber Reinforced Polymer (FRP), FiberMax Composite Crane Pads are unaffected by fluids, chemicals, or UV, and will not rust, rot, or degrade in extreme hot, cold, or maritime environments. With a minimum 20+ year service life, these lightweight crane mats will safely support your equipment, protect your people, cut operating costs, and provide you with peace of mind.

- Made in the USA.

- Up to 1,000 psi crush ratings and 400,000 lbs. rated capacities. Designed to support and stabilize mobile cranes up to 500 tons.

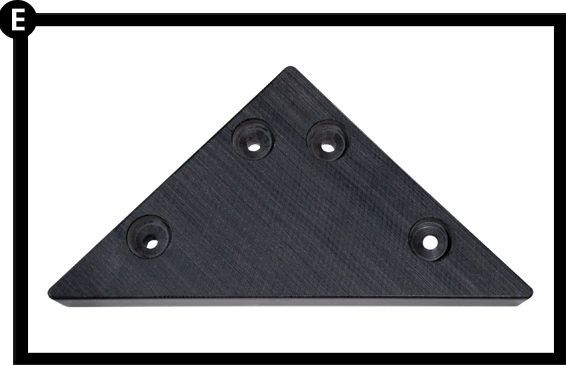

- Patented unibody, FRP bi-directional internal core, distributes load in all directions to maximize load distribution.

- FiberMax Crane Pads are nonabsorbent, easy to clean and eliminate site to site contamination.