Determining Your Soil Bearing Capacity

Before setting up a crane or other equipment with outriggers it’s essential to know the ground conditions to keep equipment upright. Knowing the strength of the ground helps operators plan for and determine the pad area needed to reduce bearing pressures to levels the ground can withstand.

As an outrigger and crane pad manufacturer, DICA works with operators in various industries using heavy equipment to determine which pad or mat would best fit their needs.

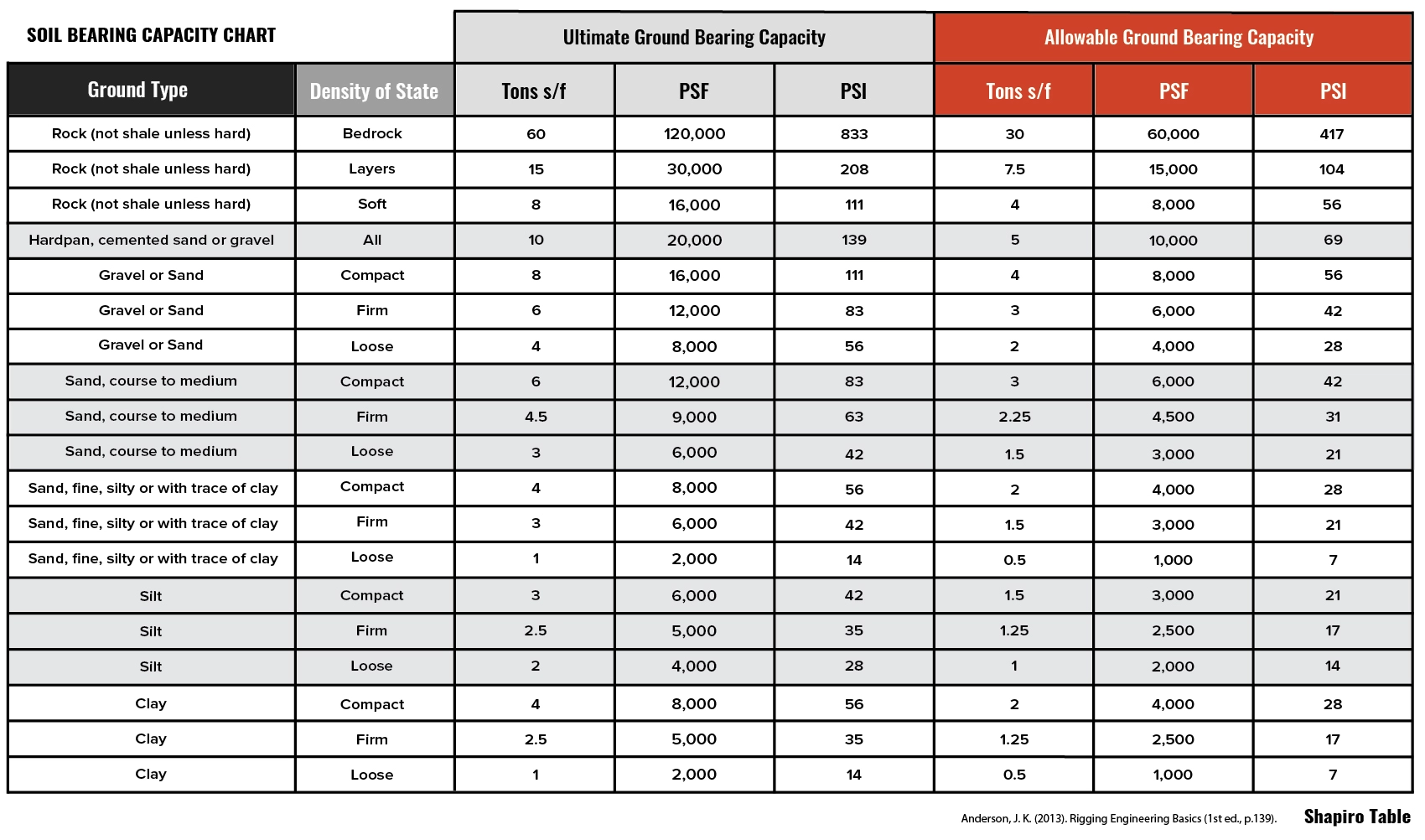

The chart below is based on general ground conditions, the assumed Ultimate Ground Bearing Capacity and calculated Allowable Ground Bearing Pressure (AGBP) for the different ground types.

When evaluating ground conditions, these are important terms to know:

Ultimate Ground Bearing Capacity

The maximum amount of vertical pressure that can be applied to the ground surface, at which point failure develops in the supporting soil. This number is typically determined by a civil engineer, or someone who is trained and experienced in the science of determining the strength and stiffness of the ground.

Allowable Ground Bearing Pressure

(AGBP) may be specified by the controlling entity to help ensure pressures imposed on the ground will stay below levels the ground is believed to be able to support. Typically, the AGBP is calculated by dividing the Ultimate Ground Bearing Capacity, by a factor of safety. The generally accepted factor of safety for temporary loading is two.

Example Calculation

-

- The Ultimate GBP = 5,000 psf

- The AGBP = 2,500 psf (5,000 psf / 2 = 2,500 psf)

- This approach helps mitigate ground failure issues due to overloading.

Example Calculation

-

- The Ultimate GBP = 5,000 psf

- The AGBP = 2,500 psf (5,000 psf / 2 = 2,500 psf)

- This approach helps mitigate ground failure issues due to overloading.

Soil Bearing Capacity Chart

Best Practices to Determine Soil Bearing Capacity

Assessing the ground conditions should be done by a qualified individual because so many factors— such as water, excavations, underground utilities or hazards—need to be considered. Before starting a project the operator must evaluate the jobsite to determine the best location to set up and to assess the ground.

Several methods exist to identify and understand the soil bearing capacity, such as:

- Documented Information

- Physical Observation

- Visual Investigation

- Field or Laboratory Testing

- Physical Testing (Plate Testing or Roll Testing)

The result of this investigation will:

- Help the operator determine if the ground needs to be improved and/or if additional pads, matting, dunnage or cribbing is needed.

- Provide a key piece of information needed to determine the minimum bearing area, which will determine the minimum pad (supporting materials) size and area.

Equipment Specific Planning

As noted above, determining a planned AGBP is essential to determining the minimum pad (supporting surface) area when selecting “everyday” crane pads, mats, dunnage or cribbing to a specific piece of equipment. An “everyday” pad is selected for a specific piece of equipment based on it’s area, strength and stiffness. Typical “everyday” pads are sufficient for use with the equipment based on a specific plan that includes an assumed maximum load and an AGBP.

Lift Specific Planning

Lift specific planning is generally done by a Lift Planner, or engineer. This is someone who has the experience and skill to account for all of the factors that go into planning a lift. In many cases lift planners will be given an AGBP by the controlling entity. In other situations they will have to use the methods identified above to help ensure the ground is properly accounted for.

If you’re looking for outrigger or crane pads to create safe setups, DICA can use its three-step fitting process to match a solution to your specific needs. Call us at 800-610-3422 to get started or request a quote and a member of our team will reach out.