A Visual Demonstration of How Sling Angles Impact Tension

Instructors at ITI (Industrial Training International) are known for their hands-on teaching style. Why Sling Angle Matters provides a visual reference for how tension increases as the sling angle decreases.

Not only does tension increase on the sling legs, it also increases on the rigging gear the slings are connected to. Like slings, rigging gear is rated to withstand specific loads. A handy reference for determining sling tension and rigging hardware capacities is ITI’s Journeyman Rigger Reference Card.

Not only does tension increase on the sling legs, it also increases on the rigging gear the slings are connected to. Photo Credit: Industrial Training Institute

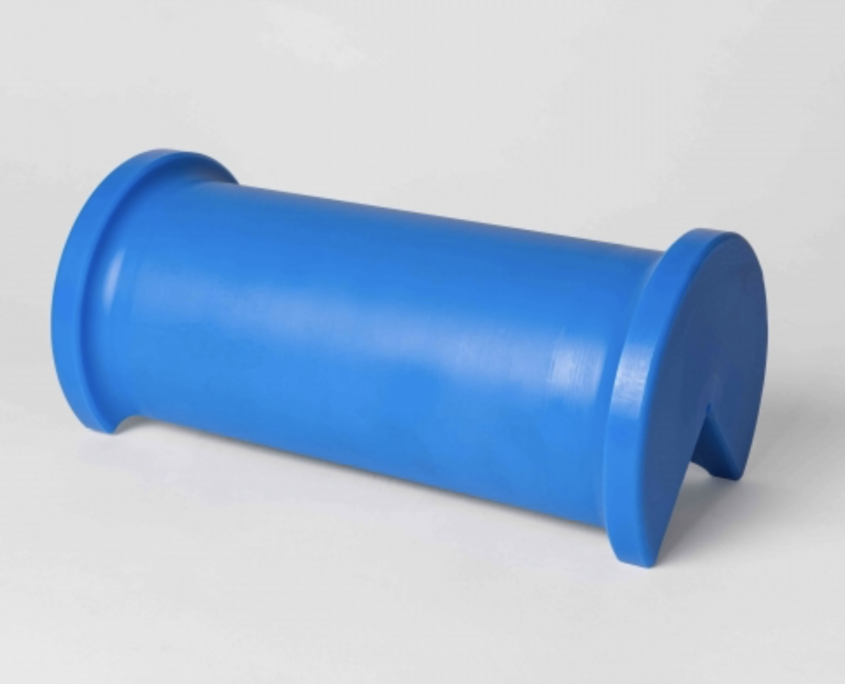

Understanding the effects of sling angles on slings and other rigging gear is a foundational rigging principle. Likewise, using edge protection is fundamental to best practices. DICA’s LiftGuard™ Sling Protectors feature a rounded surface to protect both slings and loads from damage.

DICA’s Magnetic Sling Protectors feature a rounded surface to protect both slings and loads from damage.

The capacity of LiftGuard Medium and Heavy Duty Magnetic Sling Protectors is 12,500 psi/in of sling contact. For example, a 3” diameter web sling has a contact area of 3”. Assuming the vertical and horizontal surfaces of the LiftGuard unit are in full contact with the load, the LiftGuard capacity is calculated by multiplying the contact area of 3” x 12,000. In this case the resulting capacity per sling protector would be 36,000 lbs. LiftGuard Magnetic Sling Protectors are available as standard units, Groove units, or Coil units. Custom solutions can be created to address unique needs.