SAFETYTECH

OUTRIGGER PADS

Engineered for strength, rigidity and maximum load distribution in an easy to use, unbreakable outrigger pad. Built using DICA’s proprietary engineered thermoplastic material, every SafetyTech® Outrigger Pad is designed and sized to never physically or functionally fail.

DICA outrigger pads, stabilizer pads and crane pads are put to the test daily in demanding industries including electric utility, crane rental, construction, tree care, concrete pumping, mining and drilling operations and all five branches of the U.S. armed forces and NASA.

- Made in the USA.

- Up to 500 psi crush ratings and 210,000 lbs. rated capacities.

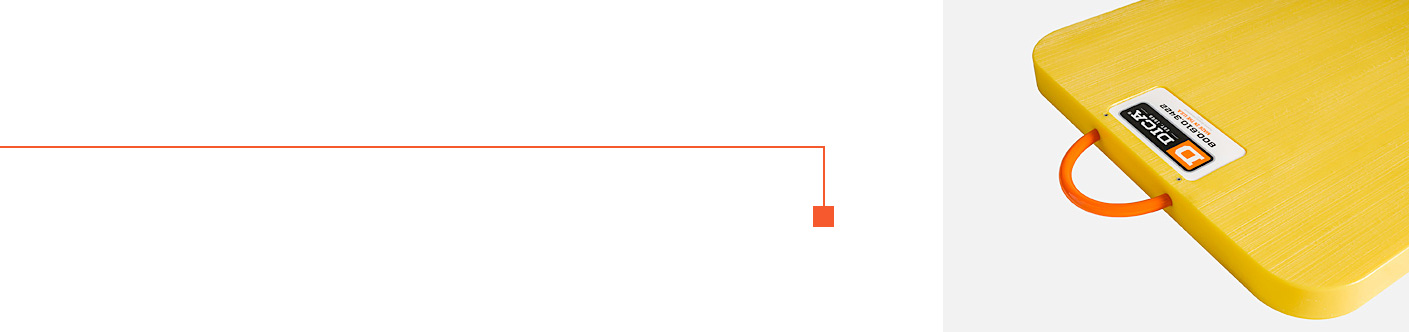

- Proprietary material, TuffGrip Handles, radius edges and corners, industrial grade safety texturing, non-conductive, engraved weight and model.

- Guaranteed unbreakable and trusted by operators in 50+ countries and 7 continents around the world.